Drill Stop Kits: What To Know Before You Buy

To view Ruland's Drill Stop Kit product page, click here.

Drilling repeatable holes is important in most hole making applications, domestic and industrial. While machines can repeatedly and precisely drill holes there are many factors that may make using one infeasible. Unfortunately, humans don't have the repeatability of machines — this is why drill stop kits exist.

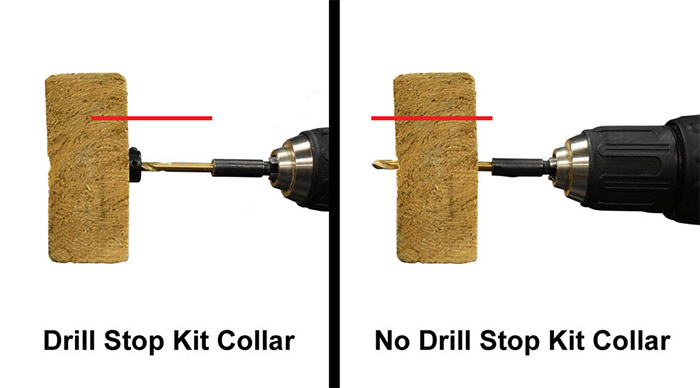

There are a few styles of drill stop that help ensure uniform hole depth in manual applications, but the most common and practical approach is to use a shaft collar as a physical stop to prevent the drill from plunging too far into the material.

When the depth is properly measured, using a shaft collar as a drill stop will help you drill holes with uniform depth quickly and easily.

What's In A Collar?

Since serving as a drill stopper is not a particularly heavy duty application for a shaft collar it might seem like selection should be easy, but this could not be less true. Most drill stop kits only include set screw shaft collars which are more than capable of handling the loads required. The design of the set screw collar is its biggest flaw with the screw needing to impinge on the drill bit. This creates a raised burr and permanently damages the shaft making adjustments, removal, and future installation challenging if possible.

Using a set screw style shaft collar permanently mars the shaft or drill bit.

One-piece clamping style shaft collars are an advancement over set screw types and have superior performance. Torqueing clamping style collars on your drill is just as simple as torqueing set screw collars, but clamping collars do not mar the shaft and have higher holding power.

Poorly constructed shaft collars may also have poor face to bore perpendicularity creating uneven surface contact between the face of the collar and material being drilled, resulting in holes that may be crooked, less uniform in thickness, and/or inconsistent.

How To Install A Drill Stop Collar

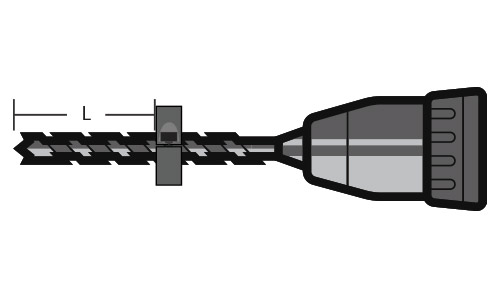

To install a one-piece clamp style shaft collar on your drill, slide the drill bit through the bore (make sure they match). Measure from the tip to the nearest collar face (L).

When L is equal to your desired hole depth install the collar by using a hex key wrench to torque the collar until it is firmly and evenly clamping the drill. Using this drill and shaft collar combo will make drilling holes with a depth of L quick and easy.

Drill Stop Kits

While single shaft collars with a bore that matches a single drill bit size can be purchased, it is simpler and more cost effective to choose a drill stop kit instead. Drill stop kits generally include seven shaft collars with bores that match common drill bit sizes (1/8”, 3/16”, ¼”, 5/16”, 3/8”, 7/8”, 1/2") as well as the necessary hex wrenches to assemble the shaft collar. Choosing a drill stop kit with clamp style shaft collars will protect drill bits from damage and ensure a full service life.