- Category

About

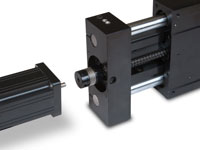

Automation & Linear Motion

EXPLORE >>

Automation and linear systems use a wide range of industrial components to achieve their desired function. Ruland provides shaft couplings, adjustable handles, rubber bumpers, and vibration isolation mounts for these systems allowing designers to specify many of the small components needed to match application requirements.

The need for automation and linear systems is increasing as a wider variety of industries have adopted technologies and processes that require accurate and repeatable motion control. As a result, these increasingly complex systems demand things like one-to-one power transmission, easier adjustability, and reduced vibration, achievable only through design using the right mix of high performance components.

Conveyors

EXPLORE >>

Conveyors are one of the most common industrial applications. Their widespread use means the components needed can vary greatly between systems. For example, a conveyor in a food processing plant will have different needs than one moving wafers through a semiconductor factory. Ruland manufactures and distributes a wide range of components to meet the needs of almost any conveyor.

Encoders

EXPLORE >>

Encoder shaft couplings and collars from Ruland are designed to meet the varied and demanding needs presented by encoders. Encoders are a component designed to pair with servo motors to resolve position, speed, and other factors to keep the application performing as expected. There are many different types of encoders such as absolute, incremental, and optical. With so many types of encoders available, they can serve virtually any need a system designer requires. This presents a challenge when it comes to selecting components such as shaft collars and couplings. Ruland offers the widest standard range of alternatives for system designers to allow them to work with off the shelf components that can be quickly sourced.

Food Processing

EXPLORE >>

Food processing equipment require a diverse range of components due to various requirements in the operating environment such as washdown, high temperature, and caustic chemicals. Ruland manufactures shaft collars and couplings in a variety of sizes, styles, and materials and supplies adjustable handles, modular mounting systems, universal joints, and other components to meet these demands. Design engineers benefit from using Ruland because they can select many standard in-stock parts from a single source.

Machine Tool

EXPLORE >>

Machine tools such as CNC mills, lathes, bar feeders, and honing machines are used by most manufacturing companies to improve production processes and performance. Although there are many types, machine tools use a variety of machine components to function smoothly and safely.

Machine tools are capable of fast, accurate, and repeatable operations due to their high level of programmability and automation. Machine tool designers must balance these performance characteristics with the diversity of applications that a machine can encounter. For example, the same machine may be used by one company to make small medical devices that weigh a few grams while another company makes industrial fixtures that weigh a hundred pounds. The design of the standard machine needs to be able to accommodate both applications without any customization. Ruland shaft collars, couplings, and other machine components are designed for high performance and convenient machine tool operation

Medical

EXPLORE >>

Medical and lab equipment use a variety of machine components to achieve precise measuring and handling operations. Ruland provides shaft collars and couplings, adjustable handles, and modular mounting systems for these applications allowing designers to specify many of the small components needed to match application requirements.

Medical and lab equipment often requires one-to-one power transmission, adjustability, and environmental compliance to prevent contamination. It is common for designers to select high performance components, often made of stainless steel, to ensure system such as test and measurement, liquid handling, and precision imaging perform as expected.

Motors

EXPLORE >>

Ruland’s variety of standard shaft collars and couplings allows designers working with motors or at a motor manufacturer to specify the right component based on the application requirements. Ruland couplings are commonly used in stepper or servo driven systems. The type of motor and what it will be driving are important considerations that affect the desired performance characteristics of a coupling. Designers need to balance specifications like torque, torsional rigidity, dampening, inertia, and shaft misalignment in order to achieve optimal performance and avoid system errors or damage. Ruland collars are used in various places throughout the internal components of the motor as a guide, spacer, or locator as well as on hollow shafts to provide a secure connection.

Packaging

EXPLORE >>

Ruland has a wide range of products to fit the needs of packaging equipment. Packaging equipment often consists of modular pieces that can be mixed and matched to meet customer requirements. The modular nature of packaging equipment leads to inch and metric components commonly being used throughout the same system. Manufacturers must offer a diverse and deep in-stock product line to service this market.

Printing

EXPLORE >>

Printing applications are made from of a variety of machine components used for guiding, spacing, mounting, adjustment, and power transmission. Compared to the systems used in other industries, printer equipment often requires manual attention, adjustment, and frequent changeouts. For this reason, systems and components that expedite and simplify the operator experience are critical.

Ruland provides many of the components necessary for printing system design such as shaft collars, shaft couplings, adjustable handles, and sensor mount systems. These components offer high levels of adjustability without compromising on performance or precision capabilities.

Robotic Systems

EXPLORE >>

The robotics industry continues to grow rapidly as the demand for automation grows in both the business and consumer markets. Robotic applications frequently require high torque and torsional rigidity during power transmission, even while demanding light weight and low inertia. Vibration control is also required in applications like cobots or material handling and articulation, which use components with dampening or vibration isolation properties.

Safety is a priority in robotic systems that handle delicate components or other critical tasks. Designers often look to incorporate axial hard stops, visual guides, and other components that ensure a robot stops or continues operation even when another part of the system fails.

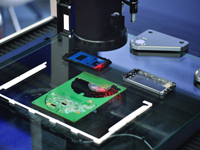

Semiconductor & Solar

EXPLORE >>

Ruland offers a variety of products designed to fit the needs of semiconductor and solar applications including shaft collars, rigid couplings, flexible couplings, adjustable handles, and rubber bumpers. The varied nature of the equipment such as machine vision systems, wafer handlers, bonders, and screen printers require similar components with performance characteristics that match application requirements.

Test Measurement and Inspection

EXPLORE >>

Test, measurement, and inspection equipment universally requires precision components to ensure reliable results, readings, and imaging. Excess vibration, unintended motion, and poorly mounted components can lead to poor system performance and excess downtime.

Ruland manufactures a variety of industrial components required for many testing, measuring, and inspecting applications. Ruland shaft collars have tight tolerances, Ruland couplings are designed for accurate, one-to-one power transmission, and components like adjustable handles and modular mounting systems are designed to offer easy solutions for adjustability and mounting challenges.

Why Ruland?

- Commitment to customer service, on-time delivery, product and engineering support.

- Products are carefully made in our Marlborough, MA factory with large stocks for same day shipment.

- Proprietary manufacturing processes have been developed over 75 years to obtain consistent performance and finefinishes.

- Raw materials are sourced from select North American mills to ensure product consistency.

- Hardware is carefully selected and tested to ensure maximum torque capabilities.

- All products are RoHS3 and REACH compliant.

CUSTOM DESIGNS

As a service to our customers, we offer our vast manufacturing experience and talents to meet special needs with custom parts. Our in-house engineering team has extensive experience designing and custom engineering solutions to meet your requirements. If you do not see what you are looking for in our standard line, please inquire about custom options.

- Special bore sizes and geometry

- Special lengths, widths, and outside diameters

- Different materials, finishes, or colors

- Custom hardware requests

- And Many Others... Please Contact Us for More Information