5 Reasons to Consider Using Jaw Couplings

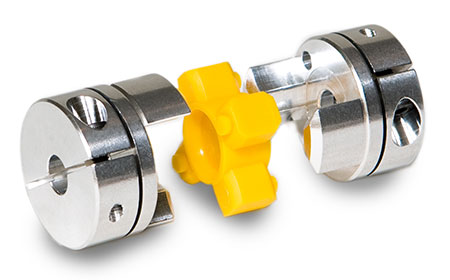

1. Balanced, Zero-Backlash Designare a three-piece assembly comprised of two that press fit onto an The press fit concentrates forces to the center of the spider’s limbs and allows the coupling to operate with zero-backlash. Jaw couplings are commonly used in servo-driven systems with high acceleration and deceleration curves where precise motion control is required and the low inertia balanced design is desired. |

|

2. Elastomer SpidersSpiders are available in three durometers allowing the user to find the right balance of stiffness and compliance in their application. The advanced polyurethane material allows the spider to absorb shock loads without damage to the motor or other sensitive system components. They serve as the wear element in jaw couplings and make for an inexpensive, simple replacement compared to other styles of coupling that require complete replacement at the end of their useable life. |

|

3. High CustomizabilityHubs with the same outer diameter can be mixed and matched and are manufactured in clamp or set screw styles, and can have inch, metric, keyed, or keyless bores. A selection of three elastomer spiders triples the potential combinations, giving designers a variety of ways to optimize their system. An additional benefit of the three-piece design allows for blind assembly in systems with limited shaft access. |

|

4. Hub SeparationRuland jaw couplings are designed to accommodate all forms of misalignment with proper spacing between both hubs. Stand offs on the spider limbs maintain proper spacing between the two hubs during installation, ensuring full misalignment capabilities. As the connecting element, the elastomer spider also interrupts electrical currents, making jaw couplings electrically isolating. |

|

5. Fail Safe DesignIf the spider fails or is otherwise compromised the jaws of the hubs interlock for direct power transmission, allowing the machine to be shut down safely. When this type of failure occurs, the spider can be replaced allowing full coupling performance to be restored. Systems that would otherwise suffer damage from sudden coupling failure benefit greatly from the continued functionality, and the sound of the hubs interlocking will alert any nearby maintenance personnel. |

|