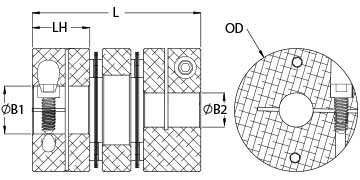

Double Disc Couplings

Ruland double disc couplings are comprised of two anodized aluminum hubs, two sets of stainless steel disc springs, and a center spacer. This design allows the sets of disc springs to bend independent of each other to accommodate all forms of misalignment, including parallel. Center spacers are available in anodized aluminum or acetal for electrical isolation. Ruland disc couplings are zero-backlash and have a balanced design for reduced vibration at speeds up to 10,000 RPM. They are a simple assembly with few moving parts, reducing the risk of backlash and premature failure. Clamp and set screw hubs are available in bore sizes from 1/8” to 1-1/4” and 3mm to 32mm.