Shaft Collar Applications

Large Bore Shaft Collars for Heavy Duty Applications

Ruland Manufacturing offers large bore shaft collars for heavy industries such as oil and gas, sand and gravel, paper, water treatment, off-highway equipment, and steel. The two-piece design allows for simple installation or disassembly without the need to remove adjacent components.

Improve Efficiency with Quick Clamping Shaft Collars

Quick clamping shaft collars are designed to deliver speed and flexibility while reducing down time. The low profile handle sits flush with the outside diameter allowing the shaft collar to be installed by hand without the need for tools. They are ideal for light duty or low-rpm applications that require frequent setup changes or adjustments.

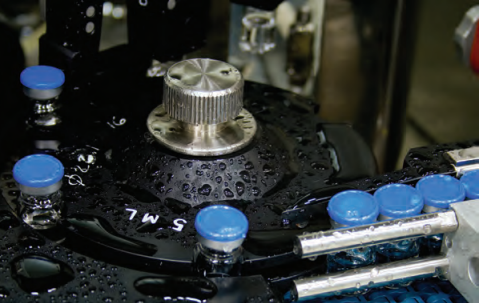

IP69K Rated Hygienic Clamping Assembly

Have an application with a shaft collar that is difficult to clean? Ruland’s patent pending hygienic clamping assembly is IP69K rated and helps protect food processing, medical and other types of equipment from excess bacteria growth by shielding them from traditional shaft collar hot spots.

Food Grade Shaft Collar

Food production and packaging lines require components that can withstand harsh cleaning agents, hot water, and high-pressure sprays to meet regulatory standards and reduce contamination. Ruland Manufacturing has developed a line of shaft collars for food processing equipment with varying levels of corrosion resistance and performance to meet industry requirements.

Quick Clamping Shaft Collars For Rapid Repositioning

Quick clamping shaft collars save you time when they are installed, repositioned, or removed. The cam lever requires no tools for actuation reducing setup or changeover time by 25% or more.

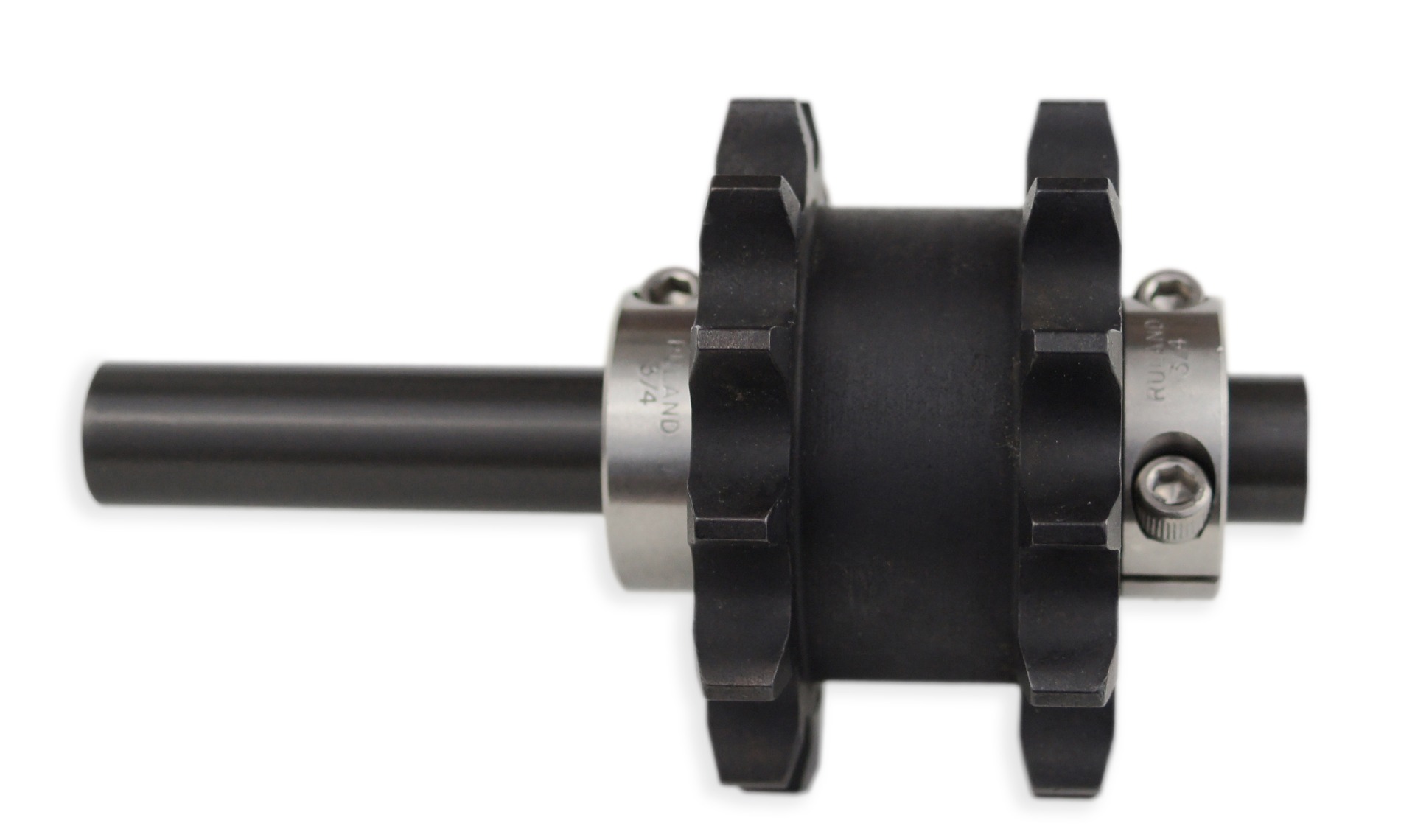

Shaft Collars for Gearboxes

Ruland clamp style shaft collars are manufactured from select materials, have fine finishes, high holding power, and precise face to bore perpendicularity making them ideal for the demands of gearboxes.

Shaft Collars as Mechanical Stops

Shaft collars from Ruland are commonly used as mechanical stops on cylinders and actuators where precise control of motion is critical. They have tightly controlled face to bore perpendicularity for increased performance in impact applications. Fastening hardware tests above industry standards for maximum torque capabilities and holding power.

Clamp Style Shaft Collars for Medical Equipment

Clamp style shaft collars from Ruland are commonly used as guides, spacers, and stops or for component alignment. Medical equipment manufacturers benefit from the tightly controlled face to bore perpendicularity of Ruland shaft collars (TIR of = .002” or .05mm) which is critical when the collar is used as a load-bearing face or for aligning components such as bearings or gears.

Hygienic Shaft Collars for Medical Equipment

Need a hygienic shaft collar that helps protect medical equipment from excess bacteria buildup? Ruland offers 303 and316 stainless steel shaft collars as well as patent pending washdown shaft collars to meet the varying levels of bacteria protection necessary in medical equipment such as cell and blood analyzers, microscopy, chromatography, pipetting, diagnostic imaging and patient positioning.

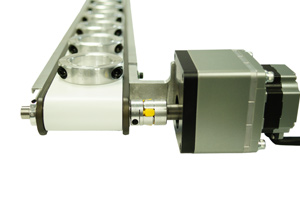

Two-Piece Shaft Collars for Packaging Equipment

Ruland two-piece type shaft collars are manufactured from select materials, have fine finishes, high holding power, and precise face to bore perpendicularity making them ideal for the demands of packaging equipment.

Shaft Collars for Packaging Equipment

Ruland clamp style shaft collars are manufactured from select materials, have fine finishes, high holding power, and precise face to bore perpendicularity making them ideal for the demands of packaging equipment.