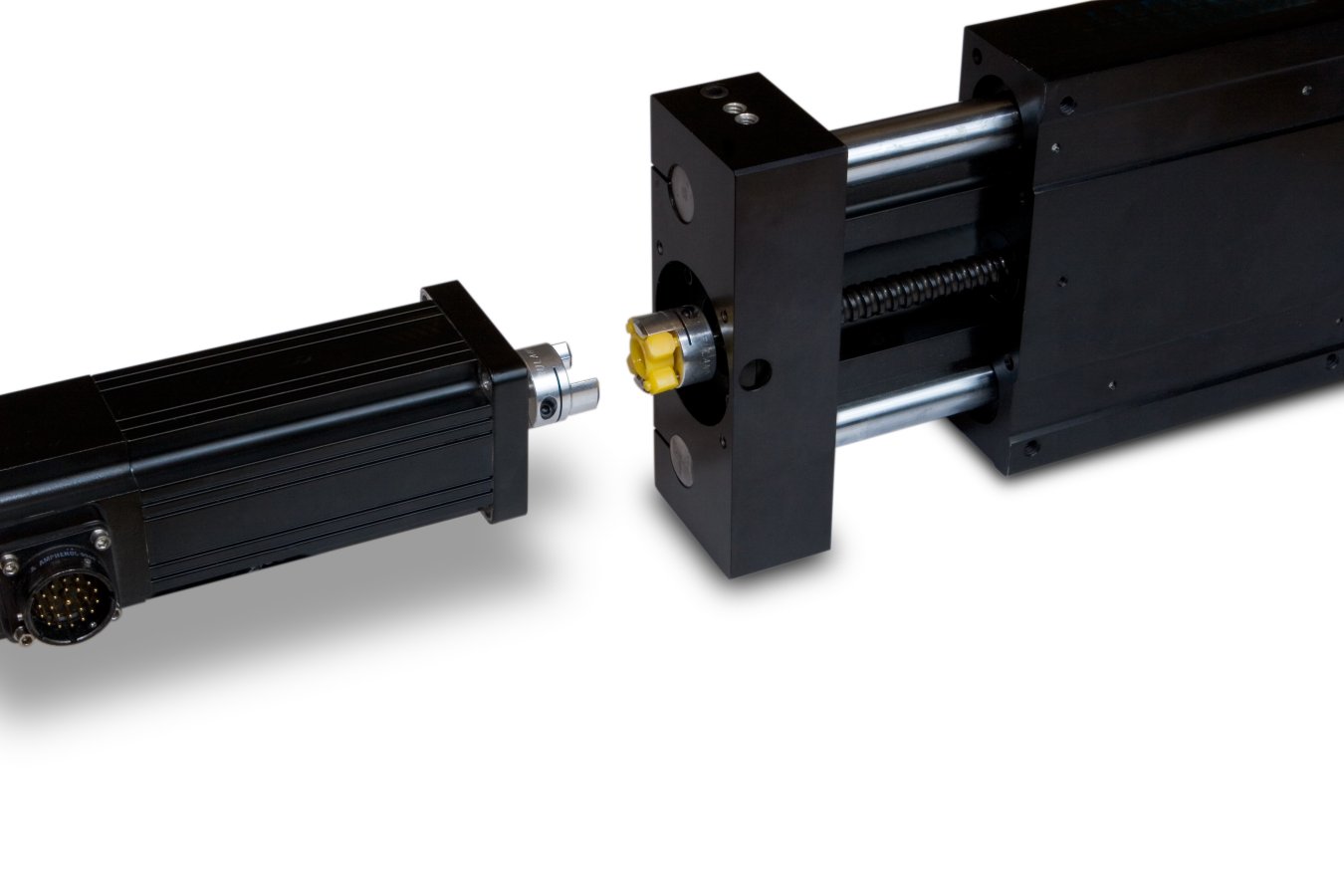

Jaw Couplings for Motors

Ruland zero-backlash jaw couplings have high dampening capabilities, can accommodate all forms of misalignment, and are highly customizable. They are well suited for applications with high acceleration and deceleration curves that have a motor coupled to a screw driven actuator or gearbox.

Zero-backlash jaw couplings are comprised of two polished aluminum hubs and an elastomeric insert called the spider. Users can combine clamp or set screw hubs with inch, metric, keyed and keyless bores. Spiders are available in three durometers – 98 Shore A for the greatest torque, 92 Shore Y for a balance of stiffness and compliance, and 85 Shore A for the highest dampening capabilities. This design allows motor manufacturers to combine standard hubs and spiders that match customer performance requirements.

Ruland uses a curved jaw profile on the hub tenons that press fit with the spider to ensure zero-backlash operation. If the spider were to fail during use the tenons on the two hubs will interlock resulting in no loss of power transmission. This allows the application to be shut down safely and prevents an abrupt stop which could cause damage to sensitive system components.

Ruland zero-backlash jaw couplings have a balanced design for reduced vibration at higher speeds which is critical when the coupling is used in a motor application where there are high acceleration and deceleration curves. They are available in bore sizes ranging from 1/8” (3mm) to 1-1/4” (32mm). All Ruland jaw couplings are carefully manufactured in our Marlborough, MA factory from bar stock sourced from select North American mills. Stainless steel hubs and spiders with a center hole are available upon request.

Jaw couplings are part of Ruland’s complete motion control coupling line which also includes beam, bellows, disc, oldham, and rigid types. Full product specifications including free downloadable CAD files, installation instructions with videos, and performance data can be found at www.ruland.com.