Beam Couplings for Motors

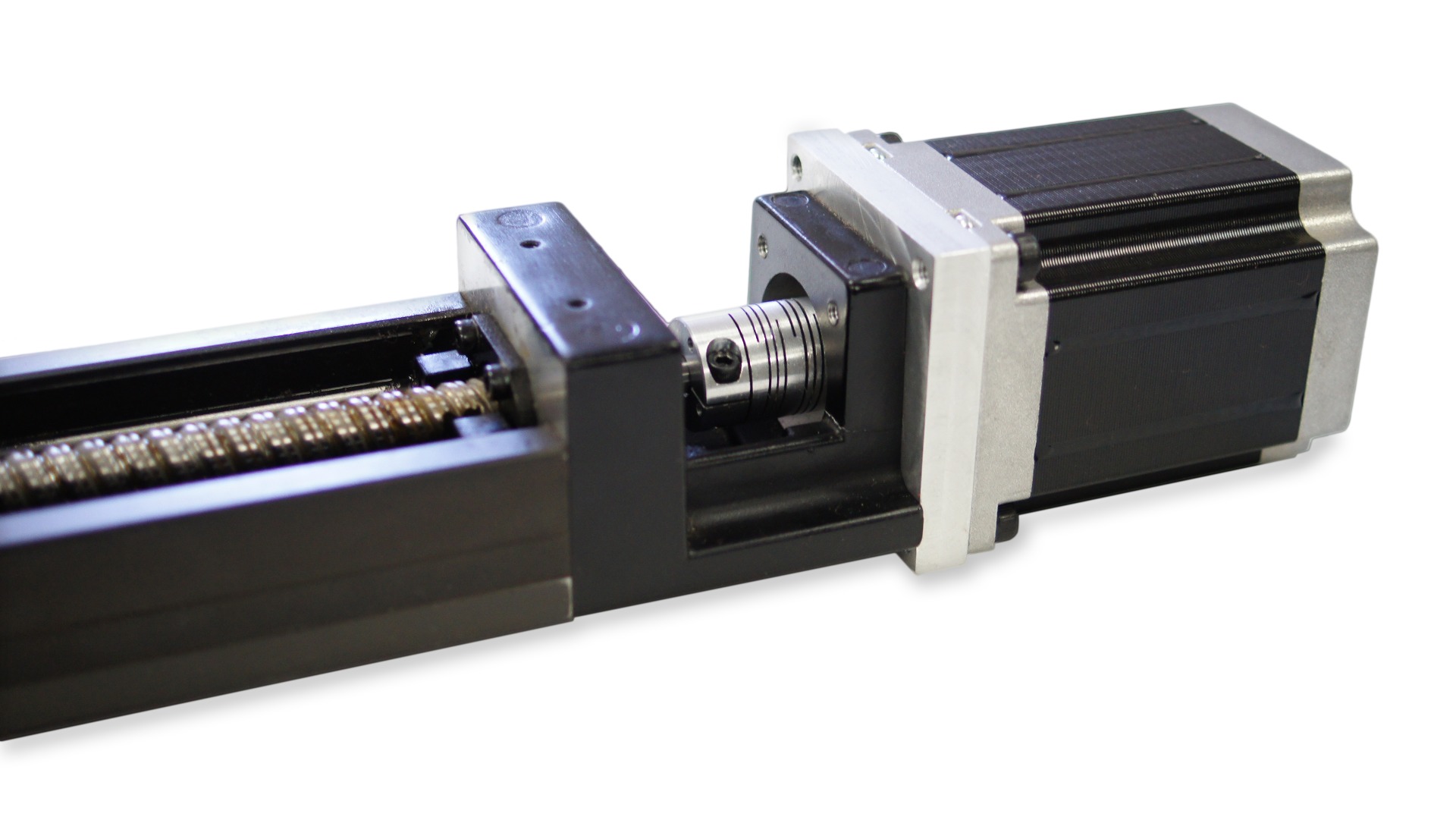

Ruland beam couplings are zero-backlash, have high torsional stiffness, accommodate all forms of misalignment, and have a balanced design, creating a highly accurate and flexible coupling. They are well suited to couple motors with encoders, lead screws, and light duty actuators in a wide variety of industries.

Stepper and servo driven systems benefit from the multiple beam design of Ruland beam couplings. They consist of two overlapping spiral cuts to increase torque capabilities and torsional rigidty when compared to the commodity style single beam coupling. Separating the spiral cuts into two sets gives the coupling better parallel misalignment capabilities while easily accommodating angular, complex, and axial misalignment.

Ruland bea, couplings are available with four or six beams in inch, metric, and inch to metric bore combinations ranging from 3/32" (3mm) to 3/4" (20mm). Four beam couplings are more flexible with lower bearing loads and are ideal for encoders while six beam couplings feature a larger body size with shorter spiral cuts to provide increased torque capability, repeatability, and torsional stiffness. Multiple beam couplings are available in aluminum for improved flexibility and low inertia or stainless steel for higher torque capacity.

All Ruland beam couplings are designed and manufactured in our Marlborough, Massachusetts factory. They are made from select North American bar stock and utilize metric fastening hardware that tests beyond DIN 912 12.9 standards. Full product specifications, 3D CAD files, technical information, and installation videos can be found on ruland.com