Rigid Couplings for Packaging Applications

Ruland rigid couplings are ideal for shaft to shaft connections, precise servo driven applications, and motor to gearbox connections commonly found in packaging equipment. They are manufactured with precision honed bores for superior fit, torque transmission, and alignment. Proprietary coating is used on hardware to reduce vibration and maintain holding power.

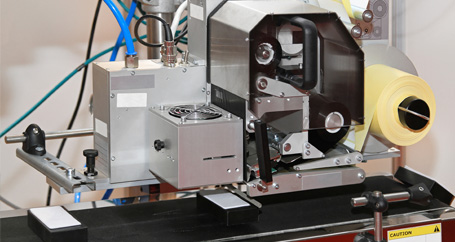

Ruland are well suited for packaging equipment including case erectors, cartoners, baggers, web converters, FFS, and labelers as they do not introduce misalignment or vibration into the system reducing wear on joined components. Straight bore rigid couplings from Ruland have precision honed bores for better fit, torque transmission, and alignment. The cross cut design accommodates slight deviations in the size of the shafts being connected for proper fit.

Ruland uses the highest grade forged screws that test beyond industry standards for maximum torque capabilities. All Ruland clamp type rigid coupling hardware is supplied with proprietary Nypatch® coating to resist vibration and maintain holding power. Nypatch® provides even seating of the screw, repeated screw installations and prevents galling. This saves a considerable amount of assembly time since screws need no additional treatments. Two-piece styles have opposing hardware for balancing, reduced vibration, and higher speed capabilities.

Rigid couplings are offered in one- and two-piece clamp styles with or without keyways in bore sizes ranging from 1/8” (3mm) to 2” (50mm). Materials are carefully selected from North American mills and include 1215 lead-free steel, high strength 2024 aluminum for low inertia, and 303 stainless steel for corrosion resistance. Ruland uses a proprietary black oxide process on steel couplings that produces a fine glossy finish while increasing holding power and corrosion resistance.