Motion Control Couplings with Inch to Metric Bores

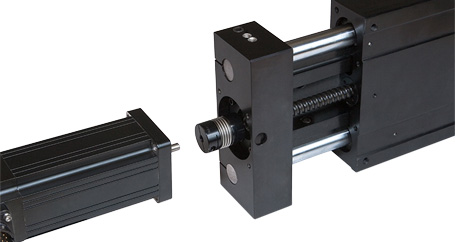

Motion systems often utilize a servo or stepper motor with a metric shaft driving a ball screw, lead screw, or encoder with an inch shaft. Coupling selection is already difficult and becomes more challenging when inch-to-metric bore combinations are needed. Ruland now offers motion control couplings with inch-to-metric bores from stock, allowing engineers to select the style that best fits their application.

Ruland now offers motion control couplings with inch-to-metric bore combinations in various sizes, styles, and materials. When selecting a servo coupling, performance factors such as torque, RPM, shaft misalignment, and space requirements should be considered. Matching application parameters to a motion control coupling can be challenging and is critical to system performance..

: Have excellent all-around performance characteristics, large misalignment capabilities, and are a good starting point. Relatively low torque and torsional stiffness when compared to other servo couplings. Bore sizes range from 1/8” to 3/4” and 3mm to 20mm.

: Highest degree of torsional stiffness for applications that require accuracy and repeatability. Suitable for speeds up to 10,000 RPM. No provision for impact loads and limited misalignment capabilities. Bore sizes range from 1/8” to 1-3/4” and 3mm to 45mm.

: Suitable for delicate equipment requiring highly precise positioning. Discs allow for misalignment while offering high torsional rigidity. Some styles are not suitable for complex or parallel misalignment. Bore sizes range from 1/8” to 1-3/4” and 3mm to 45mm.

: Dampens impulse loads and is electrically isolating. for a range of dampening and torque capacity. Low misalignment capabilities due to high bearing loads when used improperly. Bore sizes range from 1/8” to 1-1/4” and 3mm to 32mm.

: Well suited for large amounts of parallel misalignment. Offer light bearing loads, low inertia, electrical isolation, and easily interchangeable hubs. Not suitable for push-pull applications or unsupported shafts. Bore sizes range from 1/8” to 1-1/4” and 3mm to 32mm.

: Ideal for encoder or other light duty applications. Can fit in tight envelopes with lengths shorter than outer diameters. Controlflex accommodates wide variance in big bore to small bore ratio of up to 3.5:1. Bore sizes range from 1/8" to 1-1/2" and 3mm to 40mm.

: Highest speed ratings in the Ruland offering, up to 70,000 RPM due to a balanced design. Micro bore sizes start at 1.5mm for precision medical and scientific equipment. Reduced bearing loads and increased coupling life when compared to competitors due to patented radiused edges in the slit design. Bore sizes range from 1/8" to 3/8" and 1.5mm to 12mm.