The Inside Story On Ruland Shaft Collars and Couplings

Were those collars polished or prettied-up for the photographs?

No, they weren't. Those collars came from the packages right off our finished goods shelves. They all look that way. We don't make them any other way. And that Nikon will show every pimple and every dimple.

Then Isn't Ruland Overbuilding These Collars?

We don't think so. We start with a little pride. Pride inspires good workmanship, the very best that's in a person. Good workmanship always looks good, which is what you're looking at. Call it over-building, if you will, but it has proven very useful. The apparent overbuilding has resulted in cost savings for ourselves and our customers, so our prices have remained competitive.

But let's not dismiss your question about "over-building"; it's important to understand what collars do and don't do and what goes into our making good collars. With a little background, "over-building" might not seem like overbuilding anymore.

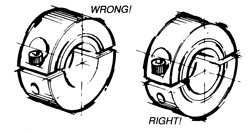

First, let's look at the set screw type with the radial set screw and a more recent clamp type version with an adjusting saw-cut and a tangentially positioned clamping screw. Within these two basic groups, there are variations in sizes and materials. Within the clamp type group, we also have threaded-bore types, shaft couplings, and two-piece take-apart types, but they all trace back to the two basic groups.

So, Where did collars come from?

The first mass-produced collars were used primarily on line-shafting in early mills. There were some bad accidents because the set screw had a protruding head that could catch a workman's clothing and pull him into a machine.

There wasn't much improvement until that fellow Hallowell got rid of the protruding square-head set screw back in the early 1900's and was awarded a patent for his safety set collar with the first recessed head socket screw. His product became the industry standard and, in time, was copied by others.

That invention, by the way, was also the beginning of the recessed socket screw industry. Today, Hallowell's company, the Standard Pressed Steel Company, is a highly regarded maker of the "UNBRAKO" line of socket screw products and a leading producer of aerospace and high-specification fasteners.

When we first looked at the industry, there were so many manufacturers and so much competition you could buy collars so cheap that you couldn't use them.

Who invented clamp type collars?

No one person invented the clamp type collar. It had been around for a long time but was more of a bother to make than the old-standard set screw style, so you didn't see one very often.

We had been producing the clamp type collar, among other things, during World War II for the bombsights and guidance instruments.

The innards of those instruments were considered very high-tech and hush-hush at that time. They were essentially mechanical with lots of precision gearing, differentials, couplings, and collars in combination with electrical selsyn motors, resolvers, precision potentiometers, and a smattering of electronics.

Those instruments were the forerunners of the analog computer industry, which kept us busy in the following years, making precision components, including shaft collars. We saw the merits of the clamp collar design that wraps around a shaft like your palm wraps around a broom handle and knew how to produce them efficiently. We proposed to make a full clamp type product range with the largest variety of standard sizes and materials to distinguish it from the old-standard set screw collar.

Aside from looks, what's so special about Ruland clamp collars?

Many details. Some are obvious, and some others are not. For one, during manufacturing, we maintain precise face-to-bore perpendicularity of TIR ≤ .002" (.05mm). This assures the squareness of that side with the bore, and we identify it with a machined groove.

What's so special about that?

We're the only supplier, as far as we know, who goes to that trouble. Others have copied the side groove, but the precise face-to-bore perpendicularity they have not. If you need that squareness for a mounting flange or a bearing face, it's already there in our clamp style shaft collars.

Doesn't Ruland use that groove on their two-piece shaft collars?

Yes. In fact, the two-piece collar really started the need for an identifying groove. Since the blanks for both our one-piece ‘CL' collars and our two-piece ‘SP' collars are the same, we used the identifying groove for both types, but for an additional reason, that is, to keep the two halves of the two-piece collars properly oriented.

What are the advantages of the two-piece shaft collar?

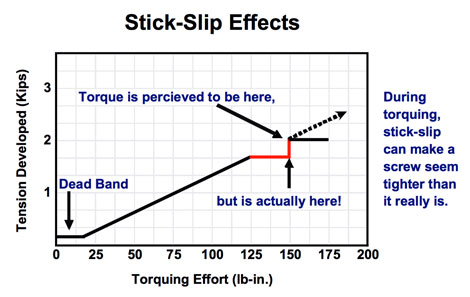

They hold a little better because that area ‘b-b' on the torque charts is missing. That's the ‘dead-ban' (see Fig. 1) on a one-piece collar. It's the area of torquing effort that doesn't do any holding because that effort is expended in closing the collar bore to meet its shaft. In the two-piece collar, all torquing effort is available since, at the outset, the collar bore is in contact with the shaft.

They are handy to have around, for they can do everything the one-piece type can do and more. They are more adaptable to varying sizes of shafting, and they can be assembled into a mechanism or disassembled without taking the whole machine apart.

|

Fig. 1 - Representation of Stick Slip (Not an actual record) |

|

| Fig. 2 - Ruland Clamp Style Collars With Alloy Steel Clamping Screws | ||||

| PART NUMBER | BORE (IN) |

CLAMP SCREW | SCREW TORQUE IN IN.-LBS |

SLIPPAGE ON SHAFT IN LBS. |

| CL-4-F | 0.250 | #4-40 | 15 | 200 (HARD) |

| CL-6-F | 0.375 | #6-32 | 28 | 600 (HARD) |

| CL-8-F | 0.500 | #8-32 | 49 | 1000 (HARD) |

| CL-8-A | 0.500 | #8-32 | 49 | 1200 (SOFT) |

| SP-8-A | 0.500 | #8-32 | 49 | 1250 (SOFT) |

| CL-10-F | .625 | #10-32 | 76 | 2400 (S0FT) |

| CL-12-F | .750 | 1/4-28 | 170 | 3500 (HARD) |

| CL-12-A | .750 | 1/4-28 | 170 | 3700 (HARD) |

| SP-16-F | 1.000 | 1/4-28 | 170 | 3000 (HARD) |

| CL-24-F | 1.500 | 1/4-28 | 170 | 2900 (HARD) |

| CL-32-F | 2.00 | 5/16-24 | 325 | 8000 (HARD) |

| CL-48-F | 3.000 | 3/8-24 | 570 | 8000 (SOFT) |

| Fig. 3 - Ruland Clamp Style Collars With Stainless Steel Clamping Screws | ||||

| PART NUMBER | BORE (IN) |

CLAMP SCREW | SCREW TORQUE IN IN.-LBS |

SLIPPAGE ON SHAFT IN LBS. |

| CL-4-SS | 0.250 | #4-40 | 8 | 150 (HARD) |

| CL-6-SS | 0.375 | #6-32 | 15 | 200 (HARD) |

| CL-8-SS | 0.500 | #8-32 | 28 | 600 (HARD) |

| SP-8-SS | 0.500 | #8-32 | 28 | 900 (HARD) |

| CL-10-SS | 0.625 | #10-32 | 45 | 800 (SOFT) |

| CL-12-SS | 0.750 | 1/4-28 | 110 | 1400 (SOFT) |

| SP-12-SS | 0.750 | 1/4-28 | 110 | 1600 (S0FT) |

| SP-16-SS | 1.000 | 1/4-28 | 110 | 1700 (HARD) |

| CL-24-SS | 1.500 | 1/4-28 | 110 | 1900 (HARD) |

| CL-32-SS | 2.000 | 5/16-24 | 190 | 2700 (HARD) |

| CL-48-SS | 3.000 | 3/8-24 | 345 | 3700 (SOFT) |

| Fig. 4 - Ruland Set Screw Collars with Alloy Steel Set Screws | ||||

| PART NUMBER | BORE (IN) |

SET SCREW | SCREW TORQUE IN IN.-LBS |

SLIPPAGE ON SHAFT IN LBS. |

| SC-4-F | 0.250 | 8-32 | 15 | 350 (SOFT) |

| SC-8-F | 0.500 | 1/4-20 | 75 | 950 (SOFT) |

| SC-10-F | 0.625 | 5/16-18 | 165 | 1500 (SOFT) |

| SC-12-F | 0.750 | 5/16-18 | 165 | 1600 (SOFT) |

| SC-12-A | 0.750 | 5/16-18 | 165 | 1400 (SOFT) |

| SC-24-F | 1.500 | 3/8-16 | 290 | 2100 (SOFT) |

| SC-32-F | 2.000 | 1/2-13 | 350 | 2900 (SOFT) |

| SC-48-F | 3.000 | 1/2-13 | 620 | 3100 (SOFT) |

| Fig. 5 - Ruland Set Screw Collars with Stainless Steel Set Screws | ||||

| PART NUMBER | BORE (IN) |

SET SCREW | SCREW TORQUE IN IN.-LBS |

SLIPPAGE ON SHAFT IN LBS. |

| SC-4-SS | 0.250 | 8-32 | 12 | 200 (SOFT) |

| SC-8-SS | 0.500 | 1/4-20 | 60 | 500 (SOFT) |

| SC-10-SS | 0.625 | 5/16-18 | 130 | 900 (S0FT) |

| SC-12-SS | 0.750 | 5/16-18 | 130 | 1100 (S0FT) |

| SC-24-SS | 1.500 | 3/8-16 | 230 | 1200 (S0FT) |

| SC-32-SS | 2.000 | 1/2-13 | 500 | 1200 (HARD) |

| SC-48-SS | 3.000 | 1/2-13 | 500 | 1800 (S0FT) |

If set screws do the job, why is Ruland making clamp style collars?

There is a need for both types. The old-standard set screw collar uses a combination of friction and shaft penetration by a hardened screw to achieve its grip on the shaft. Most of the holding ability is accomplished by the penetration of the point of the screw into the shaft.

The set screw collar doesn't do a good job in certain areas – it is much less effective on a shaft that is harder than the set screw, because there is little or no penetration.

Because holding power is linked to penetration of the set screw into its shaft, there are set screws available with points having knurls or other trick configurations, all to make a deeper penetration into the shaft. That takes the worst feature of the set screw collar and magnifies it. It can be quite a nuisance for someone who has to remove components from a shaft assembled with set collars. And, of course, it doesn't do a thing for you if the shaft is harder than the screw.

Set screw collars aren't as readily adjustable because of that "memory" matter shown in the illustration. Any and all of the above are solved with the clamp style collar. That's why we focus on clamp collars these days.

How can you tell if the set screw is harder than the shaft?

It's an interesting oddity, but in two metals that differ from each other by only a small percentage in hardness, the slightly harder one will make a good impingement on the other. If you remove a set screw from an assembly and examine the rim around the cup point, the rim itself will retain its sharp profile if the set screw is harder than its mating shaft. If the set screw is softer or only as hard as the shaft, the rim will be flattened, indicating no impingement.

What else have you observed?

You might expect, as a starting point, that the axial hold of a collar would be a reflection of the size of the clamping screw and the torque applied to that screw. It isn't always true. When we first tested collars, we found a surprising variation in performance, both in ours and in our competitors'. Our first job was to identify the causes of this variation and work on its reduction. We have made considerable progress in this area, and much of the contents of this booklet relates to this matter.

What is the major cause of this variation?

Some collars of the same type, applied similarly, showed variations in holding power. One of the major contributors to this variation is what we call stick-slip.

What is stick-slip?

It's the false impression you get that a screw has been tightened to an appropriate stress level when it hasn't. Instead of the screw rotating uniformly as the torquing effort continues, there can be a point before final torque readings have been achieved, wherein this uniform rotation converts to a stop-and-start pattern. The torsion effort on the screw is absorbed as excess friction between the threads or the underside of the head and the mating parts of the clamp body instead of contributing to stress in the joint elements. If the stresses are low, that collar will not hold well. The stick-slip condition can be elusive. A silky-smooth operation of the clamping screw during torquing is your best assurance that stick-slip is not present.

Do torque wrenches help overcome stick-slip?

No, the springiness of most torque wrenches invites this condition.

How does plating degrade holding ability?

Electroplating, especially cadmium, zinc, tin, nickel, and some phosphate coatings, performs like high film strength lubricants and can dramatically alter the holding ability because they reduce a joint's friction coefficient. Any plating deposited on the bore surface will alter this index, but these differences are easily determined. The more serious matter concerns any plating on the screw thread elements. Any change on these surfaces produces a shift in this index, making predicting the outcome much more difficult. If the normal torque is applied to the screw, the most likely result would be an over-torquing of the system, with the risk of sudden failure.

We discourage any change to the finish on our collars or their fasteners unless you have the time and the patience to go the whole distance and establish your own torquing parameters.

Incidentally, plated wrenches are not a good idea. You will find that they have a shorter useful life and more of a tendency to "cam-out" or "ream-out" than an unplated wrench of equal quality. Caution: Plating is just another level of complication.

What about the many stick-slip compounds that are available?

The problem with all of these we've seen is that they contain "extreme pressure" (EP) additives, and these compounds or additives alter the tightening characteristics of the screw. You could end up with broken screws or damaged collars. That's why we researched and developed a process that minimizes stick-slip without moving the tightening characteristics off the chart.

Why do you make such a big deal about stick-slip and plating?

Because Ruland would like to disassociate itself from any unrealistic expectations of performance based on published numbers and would like you to be aware of some elements to consider for a successful and safe design.

Why are you so insistent in using the black oxide finish?

The black oxide finish on our carbon steel collars is there for a reason. It's not any old black oxide; it's formulated to be part of the total performance of the collar. It affects the holding ability, the anti-stick slip characteristic and helps keep the torque rating of the screw within its design parameters.

Is the black oxide finish a good enough rust preventative?

Not as good as we would like. It's intended to be an internal environment protective finish, not an outside weather protective finish. But it has better rust resistance than the standard alloy socket screws that everyone accepts. And it is part of our anti-stick-slip system.

Are there places where a collar might be used but shouldn't?

Yes. They shouldn't be used to limit impact loads where people or property could be endangered if the collar failed. In designing any mechanism that calls for a person to be near moving parts, extreme care should be taken to ensure that those moving parts are constrained to do exactly what they are supposed to do and nothing else. A collar is not always enough.

If shock loads are present, these should be considered. The clamp type collar is more sensitive to shock loads than the set screw style. Remember that a collar that resists several hundred or even thousands of pounds in a static test can be shifted with a two-pound hammer. Belleville washers or a resilient buffer may be used to absorb these shocks.

Is it practical to weld these collars?

We have seen some excellent MIG and TIG welding examples: Wheelchair parts, exercise machines, and printing equipment. Because our steel and stainless steel materials contain Sulphur and other additives, the lowest possible current and adequate ventilation should be employed. Be sure to remove screws before welding.

Why does Ruland ask the designer to do his own thing?

Ruland can do a good job of manufacturing at this end and can make some tests, simulating ‘normal' conditions, but can't design at a distance, supervise at a distance, or decide what is safe and proper, as well as the person who is standing there.

Ok, so what has all of this got to do with overbuilding?

When making a product, we can detect flaws in a fine finish much more easily than in a rough finish. Measuring a part with good geometry is easier than one with poor geometry. Take, for instance, the difference between measuring a billiard ball and a potato. The true diameter of the billiard ball is easy to define, so less time is spent measuring. By comparison, it can take several trials to obtain useful information about the diameter of the potato. The earlier variations are recognized and resolved in the manufacturing process, the more economical it is to produce good collars. So, what looks like over-building costs less, sells for less, and installs for less.

How would you sum up what you've told me about shaft collars?

I mentioned something at the beginning about pride being a real asset, but I didn't answer your question fully. Pride does inspire good workmanship. Good workmanship always looks good, and that's what is so obvious in our photograph. And it isn't expensive; it actually saves money. Beyond that, pride supports a certain awareness that if you pay attention to the internal and hidden attributes of a product, the outside will take care of itself. That's why we didn't have to polish or pretty-up our product for the family photograph.

How should shaft collars be installed?

Here are a few rules to follow:

- IF YOU CAN, USE COLLARS AS YOU RECEIVE THEM. Wiping the bore and applying a thin coat of light oil to the shaft may be advisable. Do not de-grease.

- Allow testing time, especially if you plan to plate, lubricate, or rework.

- Unplated (black) wrenches are best.

- Never use a pipe extender on the wrench handle.

- As a preliminary to production applications, it's advisable to use a torque wrench to establish proper torquing parameters for that specific application.

- For maximum holding performance on Nomar® clamp style collars, it's advisable to tighten the collar until a slight resistance to rotation is felt, wring to final position, then tighten to final tension. This ensures maximum squareness, good seating, and maximum holding ability.

- Observe lower torquing standards for stainless steel hardware or on threaded elements that have been plated.

What can you tell me about rigid couplings?

Rigid couplings are intended as compact, light-duty components for timing, joining, or aligning shafts at lower speeds and torques, particularly where zero-backlash is desired. They are not intended for use as a critical part of a drive line or as a substitute for flexible or universal joints and other power transmission devices.

Why does Ruland use Nypatch® on its rigid couplings?

The Nypatch® feature is there for safety; if a screw is inadvertently left free of its load, the frictional drag of the Nypatch® feature will keep that screw from further loosening and possibly fouling or flying out of the assembly. If any screw loses its frictional drag, it should be replaced.

The clamping screws are arranged in pairs and are fairly close to each other. As a result, there is mutuality in the hoop stress developed in the coupling by each screw in each pair. So, as each screw is tensioned, it tends to relax any tension developed by its companion. Hence, we recommend that the coupling be installed by tightening the paired screws alternately in several steps so the tension is distributed more evenly. Likewise, on disassembly

What do you call your screws Nypatch®?

We weren't satisfied with the consistency of the products we could buy, so we developed our own standards and obtained a registered trademark from the Patent office.

What about shaft misalignment and rigid couplings?

Rigid couplings shouldn't be used on misaligned shafts. The lateral forces working on the coupling due to misalignment could lead to premature failure of the shafts, bearings, or couplings due to wear and metal fatigue.