Due to Microsoft's discontinuation of updates, including security, certain functionality such as checkout and CAD may not work for you. We recommend using Google Chrome, Microsoft Edge, Firefox, or Safari to ensure full functionality.Thank you - the Ruland team

Explore Similar Products

PRODUCT SPECIFICATIONS

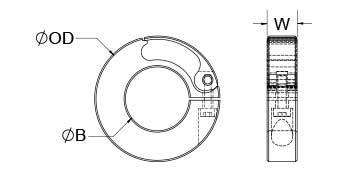

Ruland MQCL-30-A es un collarin de eje de sujeción rápida con un 30mm agujero, 50mm diámetro externo, y 13mm ancho. No se requieren herramientas para instalar o quitar, lo que permite instalaciones y ajustes rápidos así como se reduce el tiempo de inactividad. Está diseñado para aplicaciones estacionarias de trabajo ligero o de baja rotación, donde se requieren cambios frecuentes de elementos, incluidos medios, rieles de guía u otros accesorios de configuración. MQCL-30-A tiene una manija integrada que se puede utilizar solo con la fuerza de los dedos para facilitar los ajustes de colocación. El tornillo se puede ajustar para ser compatible con tolerancias de eje más amplias y proporcionar un rango amplio de fuerza de sujeción axial. Los tornillos son métricos y su prueba de fuerza supera los estándares DIN 912 129 para una capacidad máxima del par. MQCL-30-A está manufacturado a partir de material en barra que se obtiene exclusivamente de proveedores de América del Norte. Se fabrica conforme a los reglamentos RoHS3 y REACH en nuestra fábrica de Marlborough, MA EE.UU., bajo estrictos controles y mediante procesos propios.

PRODUCT SPECIFICATIONS

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

30 mm |

Tolerancia del agujero |

+0,050 mm / +0,012 mm |

|

Ancho (W) |

13 mm |

Diámetro exterior OD |

50 mm |

|

Tolerancia del ancho |

+0,076 mm / -0,254 mm |

Tolerancia del eje recomendada |

+0,000 mm / -0,013 mm |

| Fastening Hardware | |||

|

Tornillo de cabeza cilíndrica |

M3 |

Material del tornillo |

Series de acero inoxidable 18-8 300 |

|

Tamaño de la llave hexagonal |

2,5 mm |

Acabado de los tornillos |

Bright |

|

Par de apriete |

Factory Preset: 0,34 Nm, Min: 0,23 Nm, Max: 0,57 Nm |

Número de tornillos |

1 cada |

| Peformance Specifications | |||

|

Carga Axial |

Min: 311 N, Max: 445 N |

||

| Additional Information | |||

|

Especificación de material |

Cuerpo: Barra de aluminio 6061-T651, manija: Aluminio 6063-T651 |

Temperatura |

-40°C a 93°C |

|

Especificación de acabado |

Cuerpo: Anodizado con Sulfúrico MIL-A-8625 Tipo II, Clase 2 y ASTM B580 Tipo B Anodizado negro, Manija: Anodizada con Sulfúrico MIL-A-8625 Tipo II, Clase 2 Anodizado Oro con Teflón |

Fabricante |

Ruland Manufacturing |

|

País de origen |

EE.UU. |

peso |

0.038400 |

|

UPC |

634529125700 |

Tariff Code |

8483.60.8000 |

|

UNSPC |

31162811 |

||

| Product Notes | |||

|

Nota 1 |

Increasing or decreasing screw seating torque increases or decreases the axial load. Increasing torque will make it more difficult to open the handle. |

Nota 2 |

The minimum and maximum axial load data are typical values under certain test conditions and are not a guarantee of average values nor a guarantee of maximum or minimum values under all conditions. Thrust values shown are FAILURE MODE. They are shown solely for the reader to utilize appropriate testing equipment to make his/her own evaluation, and are not intended by Ruland Manufacturing Company, Inc., as warranties, either express or implied, of fitness for a given purpose. |

|

Nota 3 |

U.S. Patent No. USD629016S1 |

Prop. 65 |

|

Installation Instructions

- The MQCL-30-A quick clamping shaft collar is shipped from the factory with a pre-set screw seating torque that allows it to be used out of the box with no additional tools needed for installation.

- Use collars as they are received.

- Wipe the bore clean.

- Apply a thin coat of light oil to the shaft.

- Place the collar onto the desired shaft location with the groove side as the work surface and close the cam lever by hand. Resistance should be felt on the cam as it closes.

- Should your specific application call for fine adjustments please follow the steps to properly seat the screw.

- Open the cam lever and place the collar on the shaft at the desired location.

- Turn the M3 tensioning screw clockwise by a fractional amount (less than 1/8-turn) using a torque wrench with a 2.5 mm bit.

- Close the cam lever completely observing increased resistance as it is closed.

- Repeat tensioning screw adjustment until desired performance is achieved.

- CAUTION - Do not over-tighten the cap screw as the cam may lock in the closed position or damage to the cam mechanism may occur.

- In the event the cam lever encounters excessive resistance due to the shaft being oversized, follow the noted re-adjustment steps turning the tensioning screw counter-clockwise in this case.

WARNING This product can expose you to the chemical Nickel (metallic), known to the State of California to cause cancer. For more information go to

WARNING This product can expose you to the chemical Nickel (metallic), known to the State of California to cause cancer. For more information go to