MJC25-11-A JD16/25-85B MJC25-6-A

PRODUCT SPECIFICATIONS

PRODUCT SPECIFICATIONS

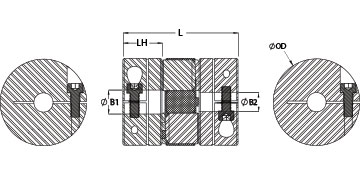

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

11 mm |

Agujero (B2) |

6 mm |

|

Diámetro exterior OD |

25,4 mm (1,000 pulg) |

Longitud L |

35,3 mm (1,390 pulg) |

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

11 mm |

Penetración del eje máximo (B1) |

11,9 mm |

|

Diámetro exterior OD |

25,4 mm (1,000 pulg) |

Tolerancia del agujero |

+0,03 mm / -0,00 mm |

|

Ancho del cubo (LH) |

11,85 mm |

Longitud L |

35,3 mm (1,390 pulg) |

|

Tolerancia del eje recomendada |

+0,000 mm / -0,013 mm |

||

| Fastening Hardware | |||

|

Tornillo de abrazadera forjado |

M3 |

Número de tornillos |

1 cada |

|

Material del tornillo |

Alloy Steel |

Acabado de los tornillos |

Black Oxide |

|

Tamaño de la llave hexagonal |

2,5 mm |

Par de apriete |

2,1 Nm |

| Performance Specifications | |||

|

Torque Specifications |

Torque ratings vary with insert selection |

Misalignment |

Misalignment ratings vary with insert selection |

|

Velocidad máxima |

8,000 RPM |

Momento de inercia |

1.464 x 10-6 kg-m2 |

|

Bearing Support Required |

sí |

Recommended Inserts |

|

|

¿Juego cero? |

Sí |

¿Diseño equilibrado? |

Sí |

|

Fail Safe |

Sí |

||

| Additional Information | |||

|

peso |

0.014800 |

Temperatura |

23°C a 82°C |

|

Especificación de material |

Barra de aluminio 2024-T351 |

Acabado |

Bright |

|

Especificación de acabado |

Bright, No Plating |

Fabricante |

Ruland Manufacturing |

|

Recommended Gap Between Hubs |

0,030 pulg (0,75 mm) |

País de origen |

EE.UU. |

|

UPC |

634529095386 |

UNSPC |

31163011 |

|

Tariff Code |

8483.60.8000 |

||

| Product Notes | |||

|

Nota 1 |

Stainless steel hubs are available upon request. |

Nota 2 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

|

Nota 3 |

Torque ratings for the couplings are based on the physical limitations/failure point of the spiders. Under normal/typical conditions the hubs are capable of holding up to the nominal torque of the spiders. In some cases, especially when the smallest standard bores are used or where shafts are undersized, slippage on the shaft is possible below the nominal torque of the spiders. Keyways are available to provide additional torque capacity in the shaft/hub connection when required. Please consult technical support for more assistance. |

Prop. 65 |

|

| Installation Instructions | |||

|

Instrucciones de instalación |

|

Video de instalación |

|

| Dimensions | |||

|---|---|---|---|

|

Diámetro exterior OD |

25,4 mm (1,000 pulg) |

||

| Performance Specifications | |||

|

Par recomendado |

15 pulg-lb (1,70 Nm) |

Desalineación angular |

1,0° |

|

Pico del par de transmisión |

30 pulg-lb (3,4 Nm) |

Desalineación paralela |

0,006 pulg (0,15 mm) |

|

Rigidez torsional |

9,3 lb-pulg/Deg (1,05 Nm/Deg) |

Momento de inercia |

0.00070 lb-in2 (2.046 X 10-7 kg-m2) |

|

Movimiento axial |

0,030 pulg (0,76 mm) |

Velocidad máxima |

8,000 RPM |

|

Bearing Support Required |

sí |

¿Juego cero? |

Sí |

| Additional Information | |||

|

peso |

0.002900 |

Temperatura |

23°C a 82°C |

|

Especificación de material |

Blue Spider |

Especificación de acabado |

Plain |

|

Fabricante |

Ruland Manufacturing |

UPC |

634529069028 |

|

País de origen |

EE.UU. |

Tariff Code |

8483.60.8000 |

|

UNSPC |

31163011 |

Recommended Gap Between Hubs |

0,030 pulg (0,75 mm) |

| Product Notes | |||

|

Nota 1 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

Nota 2 |

Torque ratings for the couplings are based on the physical limitations/failure point of the spiders. Under normal/typical conditions the hubs are capable of holding up to the nominal torque of the spiders. In some cases especially when the smallest standard bores are used or where shafts are undersized slippage on the shaft is possible below the nominal torque of the spiders. Keyways are available to provide additional torque capacity in the shaft/hub connection when required. Please consult technical support for more assistance. |

|

Prop. 65 |

This product does not require a warning. |

||

| Installation Instructions | |||

|

Instrucciones de instalación |

|

Video de instalación |

|

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

6 mm |

Penetración del eje máximo (B1) |

11,9 mm |

|

Diámetro exterior OD |

25,4 mm (1,000 pulg) |

Tolerancia del agujero |

+0,03 mm / -0,00 mm |

|

Ancho del cubo (LH) |

11,85 mm |

Longitud L |

35,3 mm (1,390 pulg) |

|

Tolerancia del eje recomendada |

+0,000 mm / -0,013 mm |

||

| Fastening Hardware | |||

|

Tornillo de abrazadera forjado |

M3 |

Número de tornillos |

1 cada |

|

Material del tornillo |

Alloy Steel |

Acabado de los tornillos |

Black Oxide |

|

Tamaño de la llave hexagonal |

2,5 mm |

Par de apriete |

2,1 Nm |

| Performance Specifications | |||

|

Torque Specifications |

Torque ratings vary with insert selection |

Misalignment |

Misalignment ratings vary with insert selection |

|

Velocidad máxima |

8,000 RPM |

Momento de inercia |

1.503 x 10-6 kg-m2 |

|

Bearing Support Required |

sí |

Recommended Inserts |

|

|

¿Juego cero? |

Sí |

¿Diseño equilibrado? |

Sí |

|

Fail Safe |

Sí |

||

| Additional Information | |||

|

peso |

0.016800 |

Temperatura |

23°C a 82°C |

|

Especificación de material |

Barra de aluminio 2024-T351 |

Acabado |

Bright |

|

Especificación de acabado |

Bright, No Plating |

Fabricante |

Ruland Manufacturing |

|

Recommended Gap Between Hubs |

0,030 pulg (0,75 mm) |

País de origen |

EE.UU. |

|

UPC |

634529067727 |

UNSPC |

31163011 |

|

Tariff Code |

8483.60.8000 |

||

| Product Notes | |||

|

Nota 1 |

Stainless steel hubs are available upon request. |

Nota 2 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

|

Nota 3 |

Torque ratings for the couplings are based on the physical limitations/failure point of the spiders. Under normal/typical conditions the hubs are capable of holding up to the nominal torque of the spiders. In some cases, especially when the smallest standard bores are used or where shafts are undersized, slippage on the shaft is possible below the nominal torque of the spiders. Keyways are available to provide additional torque capacity in the shaft/hub connection when required. Please consult technical support for more assistance. |

Prop. 65 |

|

| Installation Instructions | |||

|

Instrucciones de instalación |

|

Video de instalación |

|

WARNING This product can expose you to the chemical Ethylene Thiourea, known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to

WARNING This product can expose you to the chemical Ethylene Thiourea, known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to