Due to Microsoft's discontinuation of updates, including security, certain functionality such as checkout and CAD may not work for you. We recommend using Google Chrome, Microsoft Edge, Firefox, or Safari to ensure full functionality.Thank you - the Ruland team

Explore Similar Products

PRODUCT SPECIFICATIONS

PRODUCT SPECIFICATIONS

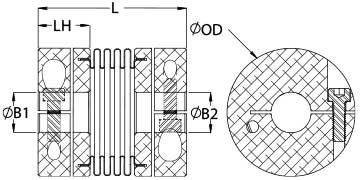

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

11 mm |

Agujero (B2) |

7 mm |

|

Penetración del eje máximo (B1) |

15,9 mm |

Penetración del eje máximo (B2) |

15,9 mm |

|

Diámetro exterior OD |

25,4 mm (1,000 pulg) |

Tolerancia del agujero |

+0,03 mm / -0,00 mm |

|

Longitud L |

1,345 pulg (34,2 mm) |

Tolerancia del Longitud |

+/- 0,76 mm |

|

Ancho del cubo (LH) |

11,85 mm |

Tolerancia del eje recomendada |

+0,000 mm / -0,013 mm |

| Fastening Hardware | |||

|

Tornillo de abrazadera forjado |

M3 |

Material del tornillo |

Alloy Steel |

|

Tamaño de la llave hexagonal |

2,5 mm |

Acabado de los tornillos |

Black Oxide |

|

Par de apriete |

2,1 Nm |

Número de tornillos |

2 cada |

| Peformance Specifications | |||

|

Reversión del par dinámico |

1,70 Nm |

Desalineación angular |

1,5° |

|

Par dinámico sin reversión |

3,40 Nm |

Desalineación paralela |

0,10 mm |

|

Par estático |

6,8 Nm |

Movimiento axial |

0,30 mm |

|

Rigidez torsional |

27 Nm/Deg |

Momento de inercia |

2.717 x10-6 kg-m2 |

|

Velocidad máxima |

10,000 RPM |

Bearing Support Required |

sí |

|

Average Load at Max Parallel Offset |

3.71 N |

Average Slope |

30.5 N/mm |

|

¿Juego cero? |

Sí |

¿Diseño equilibrado? |

Sí |

| Recommended Installation Tools | |||

|

Recommended Torque Wrench |

Recommended Hex Key |

||

| Additional Information | |||

|

Especificación de material |

Cubos: Barra de aluminio 2024-T351 |

Temperatura |

-40°C a 93°C |

|

Especificación de acabado |

Anodizado con Sulfúrico MIL-A-8625 Tipo II, Clase 2 y ASTM B580 Tipo B Anodizado Negro |

Bellows Attachment Method |

Epoxy |

|

Fabricante |

Ruland Manufacturing |

País de origen |

EE.UU. |

|

peso |

0.032300 |

UPC |

634529140369 |

|

Tariff Code |

8483.60.8000 |

UNSPC |

31163018 |

| Product Notes | |||

|

Nota 1 |

Stainless steel hubs are available upon request. |

Nota 2 |

Torque ratings are at maximum misalignment. |

|

Nota 3 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

Nota 4 |

Torque ratings for the couplings are based on the physical limitations/failure point of the metal bellows. Under normal/typical conditions the hubs are capable of holding up to the rated torque of the metal bellows. In some cases, especially when the smallest standard bores are used or where shafts are undersized, slippage on the shaft is possible below the rated torque of the metal bellows. Keyways are available to provide additional torque capacity in the shaft/hub connection when required. Please consult technical support for more assistance. |

|

Prop. 65 |

|

||

Installation Instructions

- Align the bores of the MBC25-11-7-A bellows coupling on the shafts that are to be joined and determine if the misalignment parameters are within the limits of the coupling. (Angular Misialignment: 1.5°, Parallel Misalignment: 0.10 mm, Axial Motion: 0.30 mm)

- Fully tighten the M3 screw on the first hub to the recommended seating torque of 2.1 Nm using a 2.5 mm hex torque wrench.

- Before tightening the screw on the second hub, rotate the coupling by hand to allow it to reach its free length.

- Tighten the screw on the second hub to the recommended seating torque. Make sure the coupling remains axially relaxed and the misalignment angle remains centered along the length of the coupling.

- The shafts may extend into the relieved portion of the bore as long as it does not exceed the shaft penetration length of 15.9 mm.

WARNING This product can expose you to chemicals including Ethylene Thiourea and Nickel (metallic), known to the State of California to cause cancer, and Bisphenol A and Ethylene Thiourea, known to the State of California to cause birth defects or other reproductive harm. For more information go to

WARNING This product can expose you to chemicals including Ethylene Thiourea and Nickel (metallic), known to the State of California to cause cancer, and Bisphenol A and Ethylene Thiourea, known to the State of California to cause birth defects or other reproductive harm. For more information go to