Due to Microsoft's discontinuation of updates, including security, certain functionality such as checkout and CAD may not work for you. We recommend using Google Chrome, Microsoft Edge, Firefox, or Safari to ensure full functionality.Thank you - the Ruland team

Explore Similar Products

PRODUCT SPECIFICATIONS

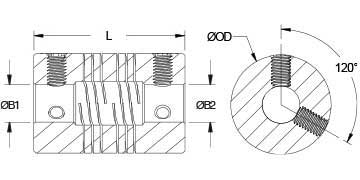

Ruland FSMR38-19-15-A, es un acoplamiento helicoidal de seis cortes con 19mm x 15mm agujeros, 38,1mm diámetro externo, y 57,2mm longitud. Está fabricado de una sola pieza y tiene tres cortes en espiral. Esto le da una mayor capacidad de par, menor torsión y el tamaño del cuerpo es más grande que los acoplamientos de uno o cuatro cortes helicoidales y permite su uso en aplicaciones de transmisión de fuerza de trabajo ligero, como acoplar un servomotor a un tornillo de avance. FSMR38-19-15-A no tiene juego y cuenta con un diseño balanceado para reducir la vibración a altas velocidades de hasta 6,000 RPM. Todos los tornillos son métricos y cumplen com más de los estándares DIN 912 129 para tener unas capacidades máximas de par. FSMR38-19-15-A está hecho de aluminio AISI 7075 para tener un peso ligero y baja inercia. Está fabricado de una barra que se obtiene exclusivamente de molinos de América del Norte y es conforme a los reglamentos RoHS3 y REACH. FSMR38-19-15-A se manufactura en nuestra fábrica de Marlborough, MA EE.UU. bajo estrictos controles utilizando procesos propios

PRODUCT SPECIFICATIONS

| Dimensions | |||

|---|---|---|---|

|

Agujero (B1) |

19 mm |

Agujero (B2) |

15 mm |

|

Penetración del eje máximo (B1) |

27,3 mm |

Penetración del eje máximo (B2) |

27,3 mm |

|

Diámetro exterior OD |

38,1 mm |

Tolerancia del agujero |

+0,025 mm / -0,000 mm |

|

Longitud L |

57,2 mm |

Tolerancia del eje recomendada |

+0,000 mm / -0,013 mm |

| Fastening Hardware | |||

|

Tornillo de fijación forjado |

M6 |

Material del tornillo |

Alloy Steel |

|

Tamaño de la llave hexagonal |

3,0 mm |

Acabado de los tornillos |

Black Oxide |

|

Par de apriete |

7,2 Nm |

Número de tornillos |

4 cada |

| Performance Specifications | |||

|

Reversión del par dinámico |

2,26 Nm |

Desalineación angular |

3,0° |

|

Par dinámico sin reversión |

4,52 Nm |

Desalineación paralela |

0,76 mm |

|

Par estático |

9,04 Nm |

Movimiento axial |

0,38 mm |

|

Rigidez torsional |

0,63 Deg/Nm |

Momento de inercia |

30.032 x10-6 kg-m2 |

|

Velocidad máxima |

6,000 RPM |

Bearing Support Required |

sí |

|

¿Juego cero? |

Sí |

||

| Recommended Installation Tools | |||

|

Recommended Torque Wrench |

Recommended Hex Key |

||

| Additional Information | |||

|

Especificación de material |

Barra de aluminio extruido y estirado 7075-T651 |

Temperatura |

-40°C a 107°C |

|

Especificación de acabado |

Bright, No Plating |

Fabricante |

Ruland Manufacturing |

|

País de origen |

EE.UU. |

peso |

0.124500 |

|

UPC |

634529011386 |

Tariff Code |

8483.60.8000 |

|

UNSPC |

31163003 |

||

| Product Notes | |||

|

Nota 1 |

Torque ratings are at maximum misalignment. |

Nota 2 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

|

Nota 3 |

Torque ratings for the couplings are based on the physical limitations/failure point of the machined beams. Under normal/typical conditions the hubs are capable of holding up to the rated torque of the machined beams. In some cases, especially when the smallest standard bores are used or where shafts are undersized, slippage on the shaft is possible below the rated torque of the machined beams. Please consult technical support for more assistance. |

Prop. 65 |

|

Installation Instructions

- Align the bores of the FSMR38-19-15-A six beam coupling on the shafts that are to be joined and determine if the misalignment parameters are within the limits of the coupling. (Angular Misialignment: 3°, Parallel Misalignment: 0.76 mm, Axial Motion: 0.38 mm)

- Fully tighten the M6 screws on one hub to the recommended seating torque of 7.2 Nm using a 3.0 mm hex torque wrench.

- Before tightening the screws on the second hub, rotate the coupling by hand to allow it to reach its free length.

- Tighten the screws on the second hub to the recommended seating torque. Make sure the coupling remains axially relaxed and the misalignment angle remains centered along the length of the coupling.

- The shafts may extend into the relieved portion of the bore as long as it does not exceed the shaft penetration length of 27.3 mm.

WARNING This product can expose you to the chemical Ethylene Thiourea, known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to

WARNING This product can expose you to the chemical Ethylene Thiourea, known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to