Free 2 Day Domestic

Free 2 day shipping for all domestic orders. Free Expedited shipping for all international orders over $399.

Due to Microsoft's discontinuation of updates, including security, certain functionality such as checkout and CAD may not work for you. We recommend using Google Chrome, Microsoft Edge, Firefox, or Safari to ensure full functionality.Thank you - the Ruland team

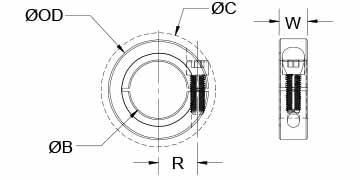

| Dimension | |||

|---|---|---|---|

|

Bore (B1) Larger inner diameter. Should match nominal shaft diameter. |

0.8750 in |

Bore Tolerance Variance in finished bore range before installation. |

+0.0020 in / +0.0005 in |

|

Outer Diameter (OD) |

1.772 in |

Clearance Diameter (C) MAX Minimum diameter required to avoid interference with hardware. |

1.89 in |

|

Width (W) |

0.394 in |

Width Tolerance |

+0.003 in / -0.010 in |

|

Recommended Shaft Tolerance Acceptable variance in nominal shaft diameter before performance loss. |

+0.0000 in / -0.0005 in |

||

| Fastening Hardware | |||

|

Forged Clamp Screw Inch or metric socket head cap screw size. |

M4 x 12 |

Screw Material |

Alloy Steel |

|

Hex Wrench Size Wrench size that fits the screw head to tighten or loosen the screw. |

3.0 mm |

Screw Finish Surface finish and treatments on supplied hardware. |

Black Oxide |

|

Seating Torque Torque required to install supplied hardware. Use torque wrench for accurate seating torque. |

4.6 Nm |

Screw Location (R) |

0.748 in |

|

Number of Screws |

1 ea |

||

| Additional Information | |||

|

Material Specification |

2024-T351 Aluminum Bar |

Bright, No Plating |

|

|

Manufacturer |

Ruland Manufacturing |

Country of Origin |

USA |

|

Temperature Minimum and maximum operating temperature. Operating temperature includes ambient temperature plus or minus factors such as system heat generated during operation, washdown, vacuum, etc... |

-40°F to 225°F (-40°C to 107°C) |

Weight (lbs) |

0.072500 |

|

UPC |

634529138496 |

Tariff Code |

8483.60.8000 |

|

UNSPC Code used to identify products to standardize nomenclature around the world. |

31162811 |

||

| Product Notes | |||

|

Note 1 |

Performance ratings are for guidance only. The user must determine suitability for a particular application. |

|

|

| CERTIFICATIONS/STANDARDS | |||

|---|---|---|---|

| ISO 9001:2015 | Conflict Minerals | ||

| RoHS3 | REACH | ||